charpy impact test paper|charpy impact test formula : importers THIS PAPER REVIEWS the Charpy V-notch (CVN) impact test and assesses its utility to characterize fracture resistance in applications to modern tough materials in contrast . Direção: Forest Whitaker. |. Roteiro Jessica Bendinger , Jerry O'Connell. Elenco: Katie Holmes , Marc Blucas , Michael Keaton. Título original First Daughter. Assista agora em .

{plog:ftitle_list}

Ultra-fast high-speed fibre home Internet. Command the faste.

Charpy tests. Material impact toughness can be measured by various types of test such as the Charpy V-notch impact test, Izod test or K IC test. The most commonly used test is the .

THIS PAPER REVIEWS the Charpy V-notch (CVN) impact test and assesses its utility to characterize fracture resistance in applications to modern tough materials in contrast .ABSTRACT: This paper provides a broad overview of the progress in procedural improvements for Charpy impact testing. It includes a short summary of early developments, a discussion of .This paper presents the results of Charpy impact test on Mild steel as measured impact force time history. A detailed Finite Element model of the Charpy impact test specimen is .

Impact testing is commonly utilized to determine the fracture characteristics of engineering materials under dynamic loading. Materials have the tendency to behave . This paper investigates using the Charpy impact test as a certification test for a production batch. First, the best conditions for surface finishing and then the Charpy impact .Presents worldwide research on the factors and variables of the Charpy test. Consists of 12 papers in sections on The Pendulum-Impact Machine; The Specimen—Notches; The . This paper provides a critical review of existing applications of the Charpy method for impact testing of cementitious composites. Studies have employed various specimen sizes and geometries. Additionally, some studies .

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a .The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away . Several researchers have recently employed the Charpy method to characterize the high strain rate mechanical strength of cementitious composites. This paper provides a critical review of existing applications of .

References [1] Holt J M 1990 Charpy Impact Test: Factors and Variables (Philadelphia: ASTM) [2] Francois D and Pinneau A 2002 From Charpy to present impact testing (Oxford: Elsevier) [3] Haušild P, Berdin C and Rossoll A 2005 Modelling of the Charpy impact test in the DBTT range Materials Science Forum 482 pp 331-334 [4] Báránya T, Czigány .In order to develop the small specimen technology in Charpy impact testing, the effects of V-notch dimensions on the test results were investigated for miniaturized specimens of a ferritic steel, Japanese Ferrite/Martensite Dual Phase Steel (JFMS). The miniaturized Charpy specimens had four different square cross-sections of 3.3, 2, 1.5 and 1 mm, and each of them had a .By doing this, it is possible to characterize how much energy different materials [with same size] can absorb. Charpy Impact Test Unit Fig. 1: Mechanical principle of the Charpy Impact Test device [2]. Results gathered from the Charpy Impact Test are important because they determine the right material for a specific application. Charpy impact test is a low cost but reliable test that breaks a notch specimen under impact loading using a hammer, and evaluates the amount of energy consumed during breakage . . Cite this paper. Pervaiz, S., Kannan, S., Ram, K., Samad, W.A. (2019). Numerical Modeling of Charpy Impact Test to Determine the Fracture Characteristics of .

The Charpy impact test, which makes use of the potential energy of a falling pendulum to fracture specimens at high strain . paper reviews the experimental details (e.g., specimen size, aspect ratio, notch provision, data normalization) of more than 20 stud-

This paper presents how a finite element model of Charpy sample fails when it is hit with an impactor. Studying the step-by-step evolution of failure of polymeric sample allows for establishing stages of the process characterising the Charpy impact, . References [1] Holt J M 1990 Charpy Impact Test: Factors and Variables (Philadelphia: ASTM .The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient . The present paper presents the results of Charpy impact testing for a variety of simulated heat-affected zone (HAZ) samples having different chemical compositions and thermal cycles. The target microstructure was coarse-grained and predominantly composed of upper bainite with martensite-austenite (MA) constituents.

charpy impact test standard pdf

Standard E 23, ―Standard Test Methods for Notched Bar Impact Testing of Metallic Materials‖. In 1901, a French researcher named Charpy published his work—the second publication in the world on pendulum machine testing—on notched bar pendulum impact tests [2]. Charpy’s tests used a pendulum impact machine based on the design developed .The objective of the Charpy impact test to ISO 148-1 is the determination of the impact energy and determination of the impact strength of a metal. The test indicates whether the metal is tough or brittle. In addition, the tough/brittle transition can be determined based on the temperature. Impact strength is a material characteristic value.

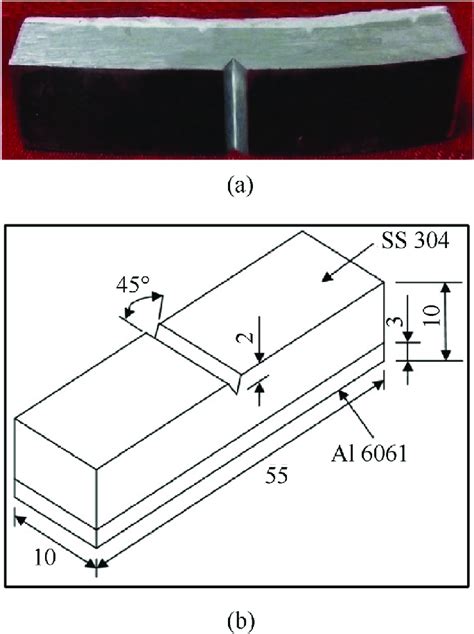

In this paper, a three-dimensional Finite Element (FE) model was performed to simulate the impact test ofnormalized carbon steel and aluminum specimens. The model specifications were developed according to ASTM E-23 standard requirements. Also the established FE model took into account all sources of non-linearity such as geometric, material and contact nonlinearities. .

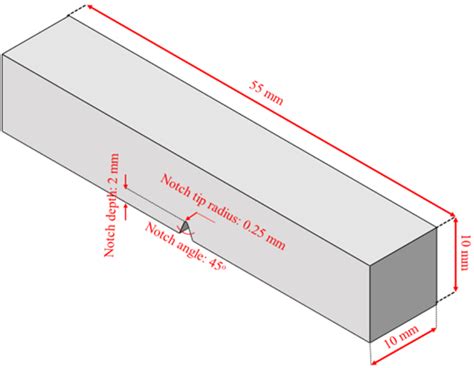

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm.This is ironic for a 100-year-old test because, as discussed in this paper, it can be reasonably argued that percent shear is the most fundamental and physically meaningful of the three Charpy parameters for brittle fracture characterization. . In a Charpy impact test, three key measurements are typically made: total absorbed energy, lateral . The case studies considered in the paper are based on previously validated Abaqus studies for the Charpy impact test [18][19] [20], the pressure vessel penetration test [21][22][23], and the .

In this paper, we present the results from Charpy V-Notch impact tests on dual phase 590 (DP590) steel, which belongs to the family of AHSS. . The influence of specimen size on Charpy impact testing of unirradiated HT-9. Nucl Mater, 155–157 (1988), pp. 662-667. View PDF View article View in Scopus Google Scholar [8]ASTM Selected Technical Papers Charpy Impact Test: Factors and Variables. By JM Holt. JM Holt 1. Alpha Consultants & Engineering? 1504 Williamsburg Place Pittsburgh, PA 15235-4924. Search for other works by this author on: . The Charpy impact test is a simple and convenient test but the end result is engineering data. To provide data for . Abstract The NIST Charpy Machine Verification Program supplies ASTM E23 certified Charpy reference specimens to customers all over the world since 1989, when the program was transferred from the US Army at Watertown Arsenal, Massachusetts.

V-notch Charpy impact test has been widely used to qualify toughness of steels and welds (e.g., [5, 6]). In this work, instrumented Charpy tests of pre-charged steel specimens were conducted at ambient temperature using a pendulum machine with a capacity of 750 J. Two to three repetitive specimens were tested for each pre-charging condition.Presents worldwide research on the factors and variables of the Charpy test. Consists of 12 papers in sections on The Pendulum-Impact Machine; Skip to Main Content. Close. Journals . ASME Journals . All Journals ; . Charpy Impact Test: Factors and Variables. 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959: ASTM . This paper provides a critical review of existing applications of the Charpy method for impact testing of cementitious composites. Studies have employed various specimen sizes and geometries. Additionally, some studies have . The result of this work is NextGen’s line of impact test equipment, which includes combined systems covering the entire range of impact test energies: Class J – Charpy and Izod Automatic Impact Testing System – 1J – 50J; Class D – Dual Column Charpy Impact Tester – 150J, 300J, 450J, 600J or 750J.

The main objective of the paper is to give the overview of the importance of mechanical properties of the materials, testing. This paper, includes the concepts of strength, plasticity, malleability, stiffness, elasticity, brittleness, ductility, . The factors responsible for the Charpy impact test are ductility, yield strength, notch .

charpy impact test standard

wood moisture meter for cannabis

Semantic Scholar extracted view of "Mechanical aspects of the Charpy impact test" by A. Rossoll et al. . Search 221,797,047 papers from all fields of science. Search. Sign In Create Free Account. DOI: 10.1016/S0029-5493(99)00017-5; Corpus ID: 111273928; Mechanical aspects of the Charpy impact test

The Charpy impact test is the mainstream test method of pendulum impact tests and is more commonly used compared to the Izod impact test. . The Film Impact Tester is used to test plastic films and paper to determine their resistance to impact-puncture. It is used to test materials such as bubble wraps and frozen food packaging bags. The paper presents and analyzes the results of experimental tests performed on two non-alloy low carbon steels (1.1141 and 1.0122) in cases of their exposure to impact fracture energy and uniaxial high cyclic mechanical stress-controlled fatigue. The experimental results provide insight into the changes in the Charpy impact fracture energy of the V-notched test .

wood moisture meter for firewood review

charpy impact test sample

WEBNeste curso de introdução à análise macroeconômica, objetivamos apresentar a estrutura lógica (modelos) da macroeconomia moderna, de maneira simples e com auxílio de gráficos básicos e intuitivos. Partiremos de uma estrutura lógica simplificada e agregada, que possibilita a compreensão intuitiva dos principais resultados encontrados .

charpy impact test paper|charpy impact test formula